Table of Contents [hide]

Who This Is For

This Hub is designed for homeowners planning a full-scale window replacement project. If you are balancing energy efficiency, long-term maintenance, and aesthetics for a standard 6 to 10 window installation, this guide provides the technical data and cost benchmarks needed to make an informed investment.

Key Takeaways

- Material Selection Impacts ROI: Choosing the right frame can improve home value and reduce energy bills by up to 12%.

- Cost Variance: Projects typically range from $16,000 to over $25,000, depending on material choice and frame complexity.

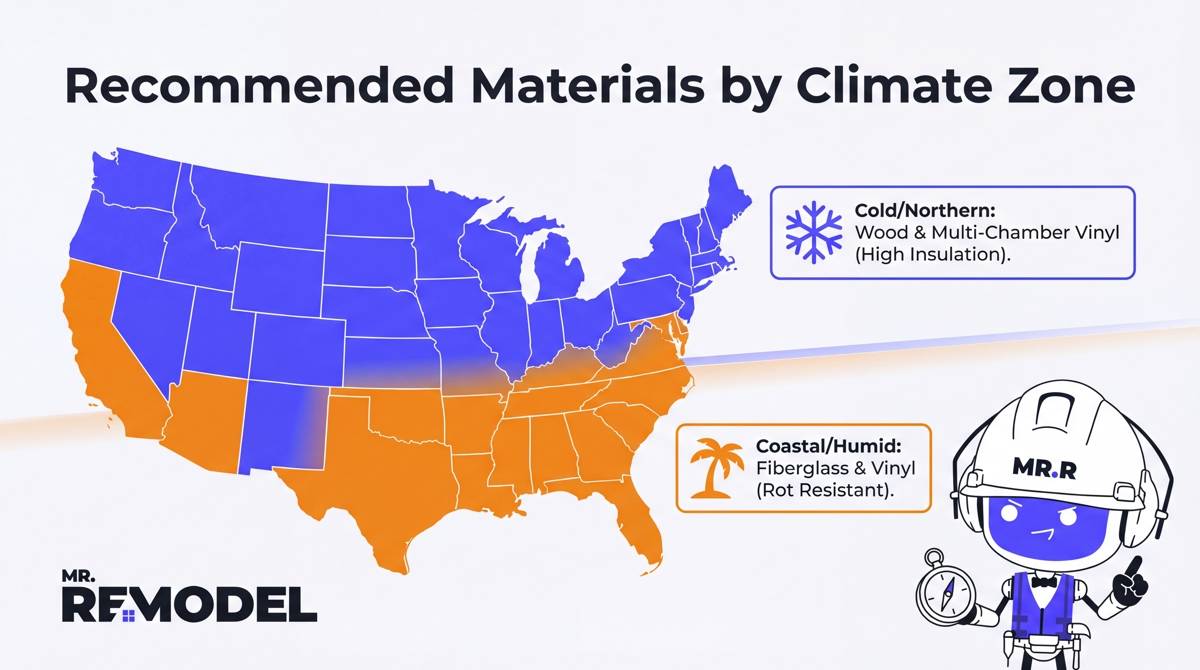

- Climate Matters: Coastal regions like Florida require moisture-resistant materials like vinyl or fiberglass to prevent rot.

- Energy Efficiency: Look for low U-factors and high R-values to maximize thermal resistance.

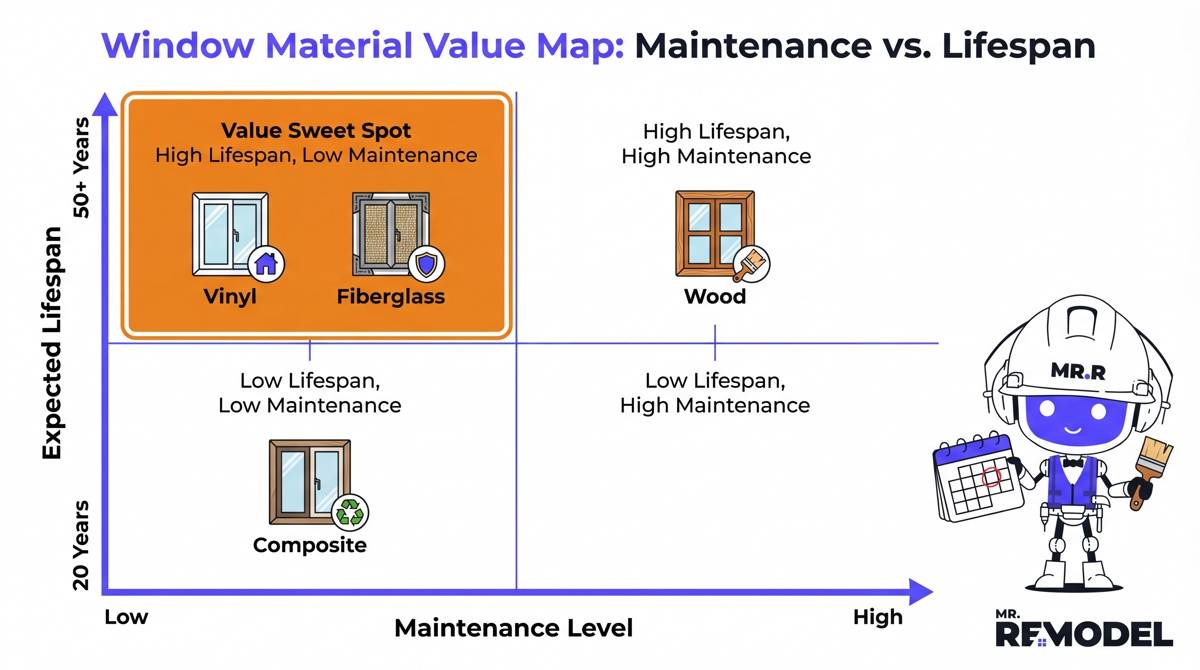

- Maintenance Levels: Wood offers the best aesthetics but requires significant upkeep compared to set-and-forget vinyl.

- Typical Project Size: Most Mr. Remodel clients replace 6 to 10 windows at once to ensure structural and aesthetic consistency.

Choosing the right window frame is no longer just about color or style. It is a high-stakes engineering decision that dictates your home's thermal envelope for the next 30 years. According to Energy.gov, heat gain and loss through windows are responsible for 25% to 30% of residential heating and cooling energy use.

At Mr. Remodel, our internal data shows the average window replacement project carries a baseline price of $16,511. This investment is heavily influenced by the raw materials used in the frames. Whether you are battling the humid coastal air of Florida or the freezing winters of the Midwest, your choice of material determines your comfort.

Vinyl Window Frames: The Performance Leader

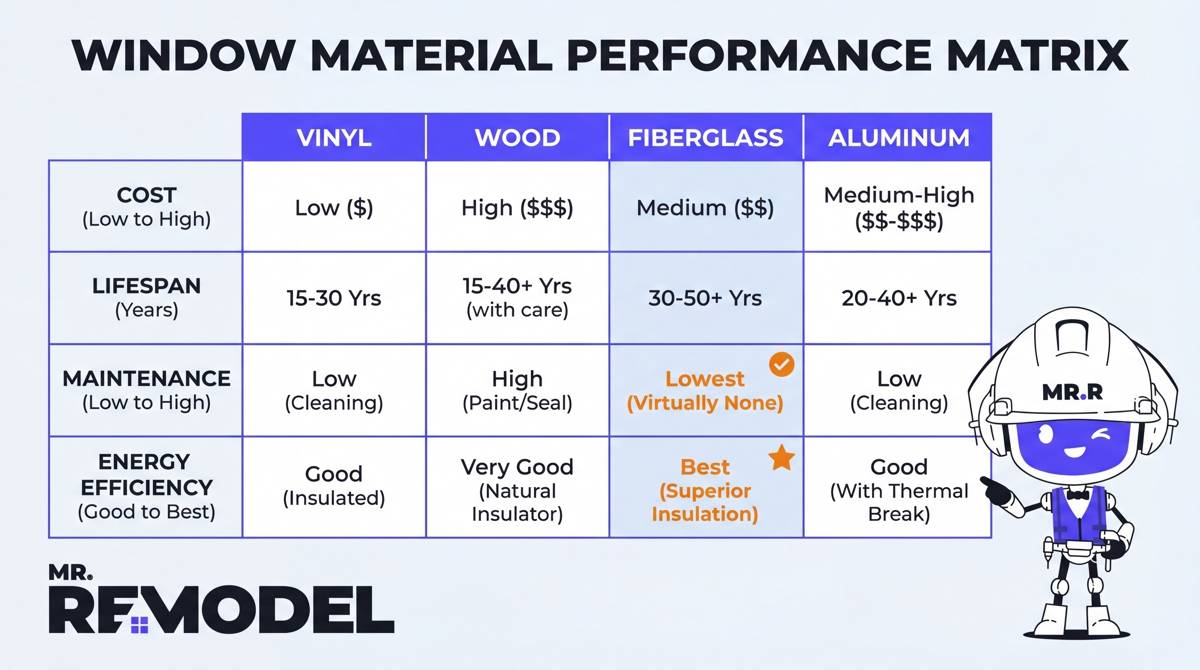

Vinyl remains the most popular choice for modern replacements due to its versatility and cost-effectiveness. Made from polyvinyl chloride (PVC) with ultraviolet stabilizers, these frames are designed to resist sunlight degradation.

Technical Advantages of Vinyl

Vinyl frames are constructed with hollow chambers. These chambers trap air, which acts as a natural insulator. This design significantly lowers the U-factor, which measures the rate of heat transfer.

According to the National Renewable Energy Laboratory (NREL), vinyl frames offer thermal performance comparable to wood without the susceptibility to moisture. This makes them ideal for the high-volume replacement markets Mr. Remodel services in humid regions.

Maintenance and Durability

Unlike wood, vinyl never needs painting, staining, or scraping. It does not rot and is impervious to termites. For homeowners looking for a one-and-done solution, vinyl is the industry standard for durability.

|

Feature |

Vinyl Specification |

|

Average Cost (per window) |

$600 to $950 |

|

Lifespan |

20 to 40 Years |

|

Maintenance Level |

Low |

|

Energy Efficiency |

High (Multi-chambered) |

See Related: Vinyl vs Fiberglass Windows

Wood Window Frames: The Aesthetic Gold Standard

Wood frames are the traditional choice for historic homes and high-end architectural designs. They provide the best natural insulation because wood has a high R-value (resistance to heat flow).

The Beauty-Maintenance Tradeoff

While wood offers unmatched interior beauty and can be painted any color, it requires a commitment. Homeowners must repaint or reseal wood frames every 3 to 5 years to prevent moisture infiltration. Without this, wood is prone to swelling, warping, and rotting.

The Wood Premium

Our data indicates that selecting wood frames can increase a standard project's total cost by 30% to 50% compared to vinyl. For a typical 10-window home, this could mean an additional $5,000 to $8,000 in material costs alone.

See Related: Vinyl vs Wood Windows

Fiberglass Frames: The Next Evolution

Fiberglass is the fastest-growing segment in the window industry. These frames are made of glass fibers and polyester resins. Because they are composed of the same material as the window glass, the frame and glass expand and contract at the same rate.

Structural Integrity

Fiberglass is significantly stronger than vinyl. This strength allows for thinner frames and larger glass areas, maximizing your view. It also provides superior air tightness, as the frames are less likely to warp under extreme temperature swings.

Environmental Resistance

Fiberglass is almost entirely immune to the elements. It does not corrode, peel, or rot. This is particularly valuable in coastal areas where salt spray can degrade other materials over time.

Aluminum and Metal Frames: Modern Strength

Aluminum windows are favored in contemporary architecture for their slim profiles and strength. However, historically, they have been poor insulators because metal conducts heat rapidly.

The Role of Thermal Breaks

To combat heat loss, modern aluminum frames include "thermal breaks." These are insulating plastic strips placed between the interior and exterior sections of the frame. GovInfo records suggest that without a thermal break, metal frames can lose significant energy during the winter months.

Best Use Cases for Aluminum

Aluminum is best suited for mild climates where thermal transfer is less of a concern. It is also the go-to choice for hurricane-prone regions because of its structural rigidity and impact resistance.

See Related: Fiberglass vs Aluminum Frames

|

Material |

Best For |

Structural Strength |

|

Vinyl |

Budget & Efficiency |

Moderate |

|

Wood |

Historic/Luxury |

High |

|

Fiberglass |

Durability & Views |

Very High |

|

Aluminum |

Modern/Coastal |

Extreme |

Composite Frames: The Hybrid Solution

Composite frames are engineered from a blend of wood fibers and thermoplastic polymers, such as PVC. This "best of both worlds" material aims to replicate the high-end aesthetic of natural wood while maintaining the low-maintenance durability of vinyl.

Why Homeowners Choose Composites

- Structural Stability: Unlike standard vinyl, composites are highly resistant to thermal expansion and contraction.

- Aesthetic Flexibility: Most composite frames can be painted, allowing you to update your home’s exterior color in the future.

- Moisture Immunity: The polymer blend prevents the wood fibers from absorbing water, effectively eliminating the risk of rot.

- Eco-Friendly Design: Many composites utilize recycled materials, making them a sustainable choice for green-conscious homeowners.

See Related: Composite Window Pros and Cons

Performance in Diverse Climates

Composites are particularly effective in regions with extreme temperature swings. Because they remain stable under stress, the seals around the glass stay intact longer, preventing the air leaks common in older wood or metal frames.

Confused by the options? Connect with Mr. Remodel for a Professional Assessment.

Comparing Costs: The 10-Window Project.

To understand the financial impact of your choice, we must look at the total project scale. Based on Mr. Remodel's average cost data, we have modeled the total investment for a standard 10-window replacement.

Total Investment Comparison Table

|

Material Type |

Estimated Cost Per Window |

Total Project (10 Windows) |

|

Standard Vinyl |

$650 |

$6,500 + Labor |

|

Premium Vinyl |

$900 |

$9,000 + Labor |

|

Fiberglass |

$1,200 |

$12,000 + Labor |

|

Wood (Clad) |

$1,500 |

$15,000 + Labor |

|

Composite |

$1,300 |

$13,000 + Labor |

Note: Total project costs include removal of old units, professional installation, and debris disposal. Labor costs typically add $3,000 to $6,000 to the totals above.

See Related: Cost to Replace Windows by City

Climate-Specific Material Selection

Your geography should dictate your material choice more than your personal style preferences. A material that thrives in the dry heat of Arizona may fail in the humidity of Florida.

The Florida & Coastal Challenge

As Florida is a top-performing region for Mr. Remodel, we emphasize materials that handle salt-spray and humidity. Vinyl and fiberglass are the recommended choices here. EfficientWindows.org highlights that moisture resistance is the primary factor in long-term window performance for these zones.

Cold Climate Performance

In northern regions, the focus shifts to the U-factor. Wood and multi-chambered vinyl provide the best "thermal break" to keep heat inside during the winter. Aluminum is generally discouraged in these areas unless a high-performance thermal break is present.

See Related: Best Window Frame by Climate

Technical Specs: U-Factor and Solar Heat Gain

When reviewing material quotes, you will encounter two critical numbers: the U-factor and the Solar Heat Gain Coefficient (SHGC).

Understanding the U-Factor

The U-factor measures how well a window prevents heat from escaping. The lower the number, the better the window is at insulating. High-quality vinyl and fiberglass frames typically achieve U-factors between 0.20 and 0.30.

The SHGC Explained

The SHGC measures how much solar radiation enters through the window. In hot climates, you want a low SHGC to keep cooling costs down. In cold climates, a higher SHGC can actually help heat your home for free during the winter.

Installation: The Invisible Variable

Even the most expensive window materials will fail if the installation is flawed. Precision is the foundation of long-term performance and home protection. A slight misalignment can compromise the entire thermal envelope of your house.

Consequences of Poor Installation

- Persistent Air Leaks: Gaps around the frame that cause energy bills to spike.

- Water Infiltration: Hidden moisture entry that leads to structural wall rot and mold.

- Operation Failure: Structural sagging that prevents windows from opening or locking correctly.

- Warranty Issues: Most manufacturers will void your warranty if the product is installed improperly.

Professional Expertise vs. DIY Risks

Window replacement is far more complex than a standard weekend DIY project. It requires technical mastery of the building envelope to ensure a weather-tight seal. Professional installers use specialized tools to manage the structural transition between the wall and the window.

Essential Installation Steps

- Precision Leveling: Ensuring the rough opening is perfectly square and level before placement.

- Advanced Flashing: Applying technical barriers to redirect water away from the interior.

- Structural Integration: Achieving a seamless fit that supports the weight of the new glass.

- Perimeter Insulation: Using specific expanding foams to eliminate thermal bridging.

Frequently Asked Questions (FAQ)

Which window material lasts the longest?

Fiberglass typically has the longest lifespan, often exceeding 50 years. It does not rot, warp, or corrode, making it the most durable long-term investment for homeowners.

How do I know if I need vinyl or wood?

If you prioritize low maintenance and energy efficiency at a mid-range price, vinyl is the best choice. If you live in a historic home or require a specific wood interior look and don't mind periodic maintenance, wood is the winner.

What is the most energy-efficient window frame?

Fiberglass and wood share the top spot for natural insulation. However, high-end vinyl frames with foam-filled chambers provide nearly identical performance at a lower price point.

Does Mr. Remodel offer financing for window projects?

Yes. Mr. Remodel provides various financing options to help homeowners manage the $16,511 average project cost, allowing you to pay for your energy-efficient upgrades over time.

Can I mix window materials in my home?

While possible, it is not recommended. Using different materials can lead to inconsistent thermal performance and aesthetic clashing. Mr. Remodel suggests replacing windows in "clusters" or doing the whole home at once for uniformity.

Why is fiberglass more expensive than vinyl?

The manufacturing process for fiberglass (pultrusion) is more complex and energy-intensive than the extrusion process used for vinyl. Additionally, the raw materials are more costly, reflecting the material's superior strength.

How does Mr. Remodel ensure a proper fit?

Mr. Remodel uses precision measurement technology for every project. We measure each opening at three different points to ensure the custom-built frames fit perfectly, eliminating the need for excessive shimming or caulking.

Are aluminum windows still used in residential homes?

Yes, but primarily in modern designs or in regions where impact resistance is the priority. For most residential replacements, vinyl or fiberglass is preferred for its superior insulation properties.

What is the average turnaround time for a Mr. Remodel installation?

Once your custom frames are manufactured, a standard 10-window installation is typically completed in 1 to 2 days by our professional crews.

How much can I save on my energy bill with new windows?

Homeowners typically see a 10% to 15% reduction in their monthly energy costs when upgrading from single-pane or leaky older frames to modern Energy Star-certified materials.

The Path to a More Efficient Home

Replacing your windows is one of the most significant investments you will make in your home's infrastructure. By choosing the right material—whether it’s the cost-effective performance of vinyl, the rugged durability of fiberglass, or the timeless beauty of wood—you are securing your home’s value and comfort for decades.

The data is clear: the right frame reduces energy waste, protects your interior from UV damage, and enhances curb appeal. Don't settle for a "one-size-fits-all" approach. Your climate, your architecture, and your budget deserve a tailored solution.

Ready to upgrade? Get your free, accurate quote and connect with local contractors who specialize in your chosen materials.